Go Green Colorless Asphalt Binder (hot mix color asphalt emulsion) is our new developed eco-friendly product, this product contain high performance asphalt modifier, high-molecular polymer, color developer, anti-aging agent, high viscosity asphalt stabilizing agent, high modulus asphalt road surface modifier etc modifiers, which make this product have economic, environmental protection, stable quality, good durability advantages.

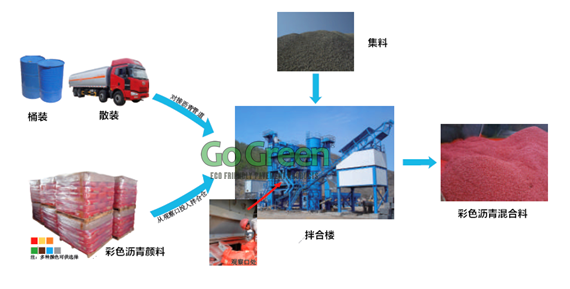

Go Green supply the colorless asphalt binder & pigment for clients to produce hot mix color asphalt locally.

During the production, mixing the colorless asphalt binder with 3% color asphalt pigment and 91% aggregate in the asphalt tank, then produce out to hot mix color asphalt mixture. The finished product should be load into lorry to the construction site, suggested paving thickness is 3cm. The colored pavement has good strength, good high and low temperature performance, beautiful and vivid color, very long lasting.

Construction process:

Production and construction process:

1. Clean the original black asphalt feeding pipeline and connect it to the colored asphalt equipment

2. Before mixing, the mixing tank of the mixing station should be cleaned.

3. The aggregate temperature is controlled between 170-190℃, and the asphalt heating temperature is 160-175℃

4. Before use, calculate the amount of pigment that needs to be added to each tank of mixture, and pour the pigment into the mixing tank. The asphalt mixture should be evenly coated, the color should be uniform, and there should be no agglomeration or segregation of coarse and fine particles.

5. Vehicles and pavers used to transport mixed materials also need to be cleaned in advance.

6. When paving, ensure continuous paving, and achieve full-width paving without interruption at one time to maintain consistent color, uniform particles, and beautiful appearance.

7. When rolling, try to ensure compaction without embossing the stone to avoid over-pressure. If the stone is crushed, the color effect will be affected.

8. Open to traffic