Go Green color emulsified micro-surfacing adopts advanced technology and production line to prepare the modified colored asphalt into slow-crack, slow-crack fast-setting and fast-crack high-grade colored polymer modified emulsified asphalt according to the application. Fine particle size, uniform distribution, stable storage, excellent adhesion and aging resistance between evaporation residues and aggregates super-viscous wear layer (color micro-surface) construction.

This product is a water-based polymer material, with normal temperature construction, energy saving and consumption reduction, ecological and environmental protection.

Colored graded aggregate : This series of products selects natural granite, uses fine crushing and screening sand making equipment, and is screened according to gradation. It has the characteristics of wear resistance, noise reduction and low water absorption. The paved colored pavement has good durability and bright colors. It is mixed with asphalt materials in a certain proportion to form a three-dimensional waterproof structure, which effectively improves the water damage resistance of the road surface and can meet the requirements of various colored road surfaces.

Instructions for use:

It is mixed with high-grade colored emulsified asphalt in a certain proportion and used for road construction such as colored high-viscosity wearing layers (colored micro-surfacing).

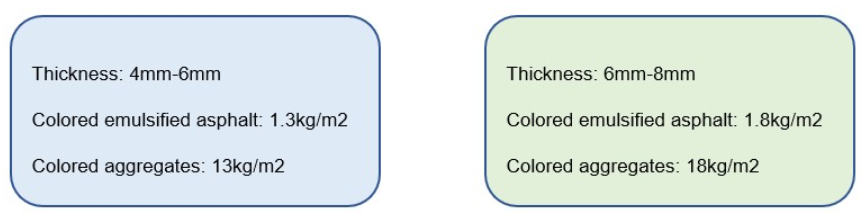

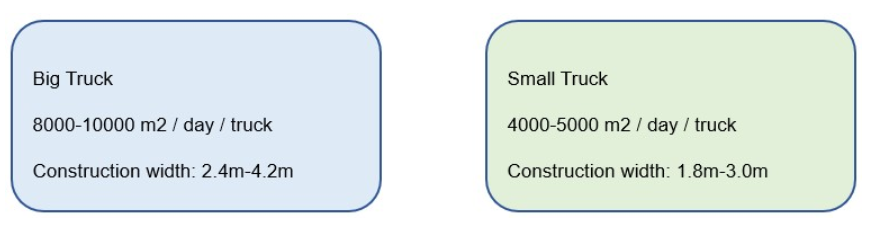

Use slurry sealing equipment to mix high-grade colored emulsified asphalt, colored anti-skid composite graded aggregate and additives evenly and spread them onto the road surface with a thickness of 4mm-6mm and 6mm-8mm. It is suitable for all levels of highway prompt sections, toll stations, service areas, bridges and tunnels, tourist highways, urban bus lanes, BRT, etc.

Construction steps:

Base treatment: remove loose soil, garbage, oil and loose parts of the original road surface, repair cracks, potholes, staggered platforms, voids and other defects on asphalt and cement pavement, and perform slope treatment to avoid water accumulation. The asphalt pavement can be constructed directly after cleaning and leveling. The cement concrete pavement should be finely milled to remove the floating slurry. After cleaning, the interface agent should be sprayed. The next process should be carried out 1 hour after the interface agent is applied;

Isolation of the construction area: Use protective tape to separate and protect the construction area to avoid contaminating the road surface, and clean it immediately after the construction is completed;

Paving: debug the equipment, add the cationic colored emulsified asphalt and colored graded aggregate to the paver in a ratio of 1:10 and stir. After fully stirring, spread the mixture evenly on the road surface with a paving thickness of about 4-6mm. The dosage is 11-12kg/m2;

Remove the antifouling tape after the pavement mixture stops flowing.

Open to traffic: generally 2-4 hours (temperature 23°C, humidity 50%) after demulsification and molding, traffic can be opened, and it can be extended appropriately when the temperature is low

Note: The temperature is required to be above 10℃ and below 35℃ for construction. No construction is allowed on rainy days. After the product is formed, large trucks are strictly prohibited from driving during use, as oil leakage will corrode the surface. Clean or clean the road surface regularly to maintain the brightness of the color.